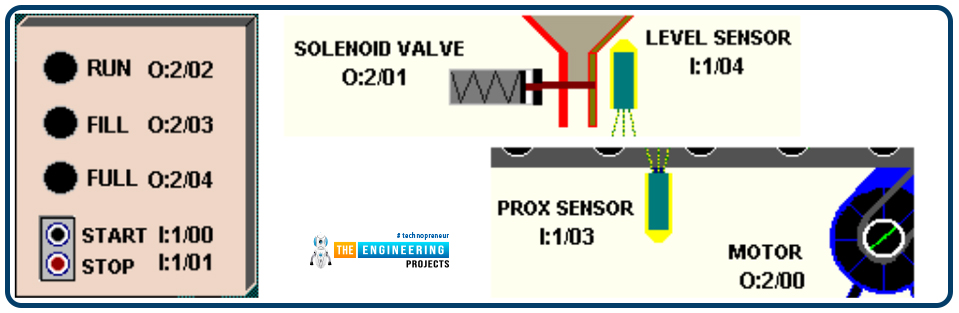

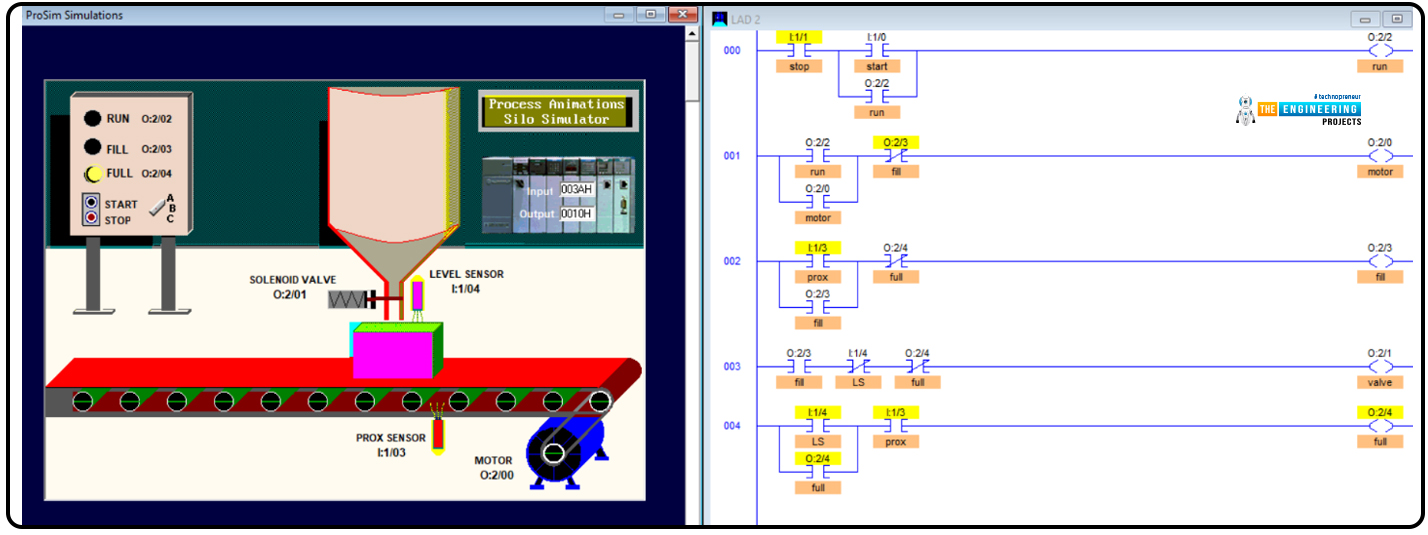

Hey guys! hope you’re all very effectively. Immediately I come to you with a brand new course of to study, program, and simulate for working towards ladder logic increasingly. The method we’re going to implement in the present day is a quite common course of that might be there in lots of many industries which is a silo course of that goals to automate the method of filling containers or bottles with a liquid. Determine 1 exhibits the whole scene of the method together with the system elements, switches, indicators, sensors, and actuators which might be built-in to make the system function. Briefly and earlier than going into deep particulars, let’s state what the system does and the way it operates. Effectively! The system mechanically fills the bins which might be touring on the conveyor which is pushed by a motor. They’re crammed with a liquid saved within the silo proven in the midst of determine 1. The method operates repeatedly from the second we hit the beginning button proven within the tail of the management panel on the left facet of determine 1 till termination of the method is requested by urgent the cease push in the identical panel. Many inputs and outputs are utilized to deal with the sensors, switches, push buttons, motors, and valves. So let’s get began on the challenge.

Venture Logic Philosophy

As we’ve got thought, step one within the improvement of a management system is to sit down with the operator or the shopper to get to understand how the system works together with all particulars and eventualities. So the system begins by receiving the kickoff by hitting the beginning pushbutton. Until there isn’t any cease has been requested or faults, the field strikes on the conveyor that’s pushed by a motor till it reaches the filling station which is on the silo. At that place, the field ought to cease for filling, and the circulate of the liquid begins and goes on till the field is full. Then, it’s time for the field to proceed its journey to the tip of the conveyor and one other field commences a brand new journey for filling. At any time a cease is requested, the system ought to halt till a command to proceed is offered. Operation standing ought to be proven due to indicators displaying the run, fill, and full standing. Now, mates, that’s all of the story we’ve got gotten by sitting with the shopper or the operator who requested us to implement his system. have understood the requested silo operation? Effectively carried out! I do know it’s easy to know however what’s the subsequent step? Sure, the subsequent station within the challenge is to interpret the story narrated by our shopper into operation sequences and situations and decide the checklist of inputs and outputs to get that challenge carried out.

Logic sequence

The goals of the challenge we’re going to implement is to implement the ladder logic program that execute the narrated logic of SILO by shopper. The logic may be resumed within the following sequence of operations:

The batch course of may be began or stopped at any level of execution

Indicator lamps ought to be appropriately managed to current the run, fill, and full statuses of the operation all through the entire course of.

All actuators ought to be stopped at any time a termination requested by the tip person

The FULL lamp is switched on displaying the total standing of the field so long as the field at its filling place beneath the silo.

After changing the logic narrative obtained from the shopper into clear logic sequences, now the time involves checklist the inputs and outputs to make use of to perform these logic sequences. Within the subsequent part, the whole checklist of inputs represented by sensors and switches and outputs represented by motors, valves, and light-weight indicators.

Venture I/Os

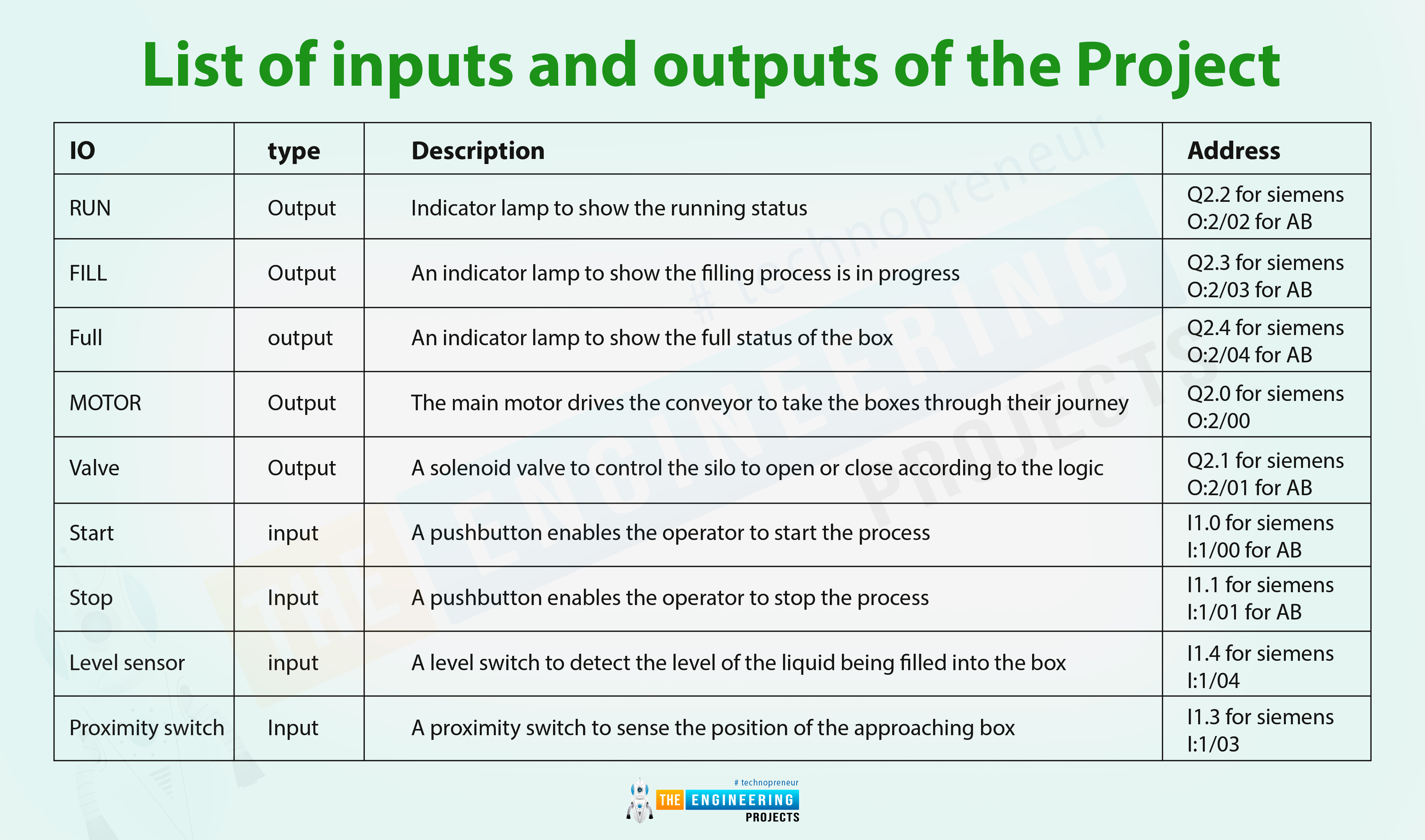

Determine 2 exhibits the situation and tackle of all inputs and outputs used on this challenge. Additionally, the desk beneath lists all inputs and outputs of the challenge together with descriptions and addresses. The management panel on the carry exhibits two inputs that allow an operator to begin and cease the operation. Additionally, it exhibits indicators displaying the standing of the operation all through the entire course of. These standing indicators are RUN. FILL, FULL to point out the method is working, the field is filling, and when it’s full. Additionally, it exhibits the motor that drives the conveyor and the proxy sensor that detects the place the place the field is strictly beneath the silo and able to be crammed for initiating the filling course of. Additionally, a stage sensor is utilized to find out when the field is crammed as much as full. As well as, a valve is used to open and shut the silo.

Desk 1: checklist of inputs and outputs of the challenge

IO

| kind

| Description

| Deal with

|

RUN

| Output

| Indicator lamp to point out the working standing

| Q2.2 for siemens

O:2/02 for AB

|

FILL

| Output

| An indicator lamp to point out the filling course of is in progress

| Q2.3 for siemens

O:2/03 for AB

|

Full

| output

| An indicator lamp to point out the total standing of the field

| Q2.4 for siemens

O:2/04 for AB

|

MOTOR

| Output

| The primary motor drives the conveyor to take the bins by means of their journey

| Q2.0 for siemens

O:2/00

|

Valve

| Output

| A solenoid valve to regulate the silo to open or shut in response to the logic

| Q2.1 for siemens

O:2/01 for AB

|

Begin

| enter

| A pushbutton allows the operator to begin the method

| I1.0 for siemens

I:1/00 for AB

|

Cease

| Enter

| A pushbutton allows the operator to cease the method

| I1.1 for siemens

I:1/01 for AB

|

Degree sensor

| enter

| A stage swap to detect the extent of the liquid being crammed into the field

| I1.4 for siemens

I:1/04

|

Proximity swap

| Enter

| A proximity swap to sense the place of the approaching field

| I1.3 for siemens

I:1/03

|

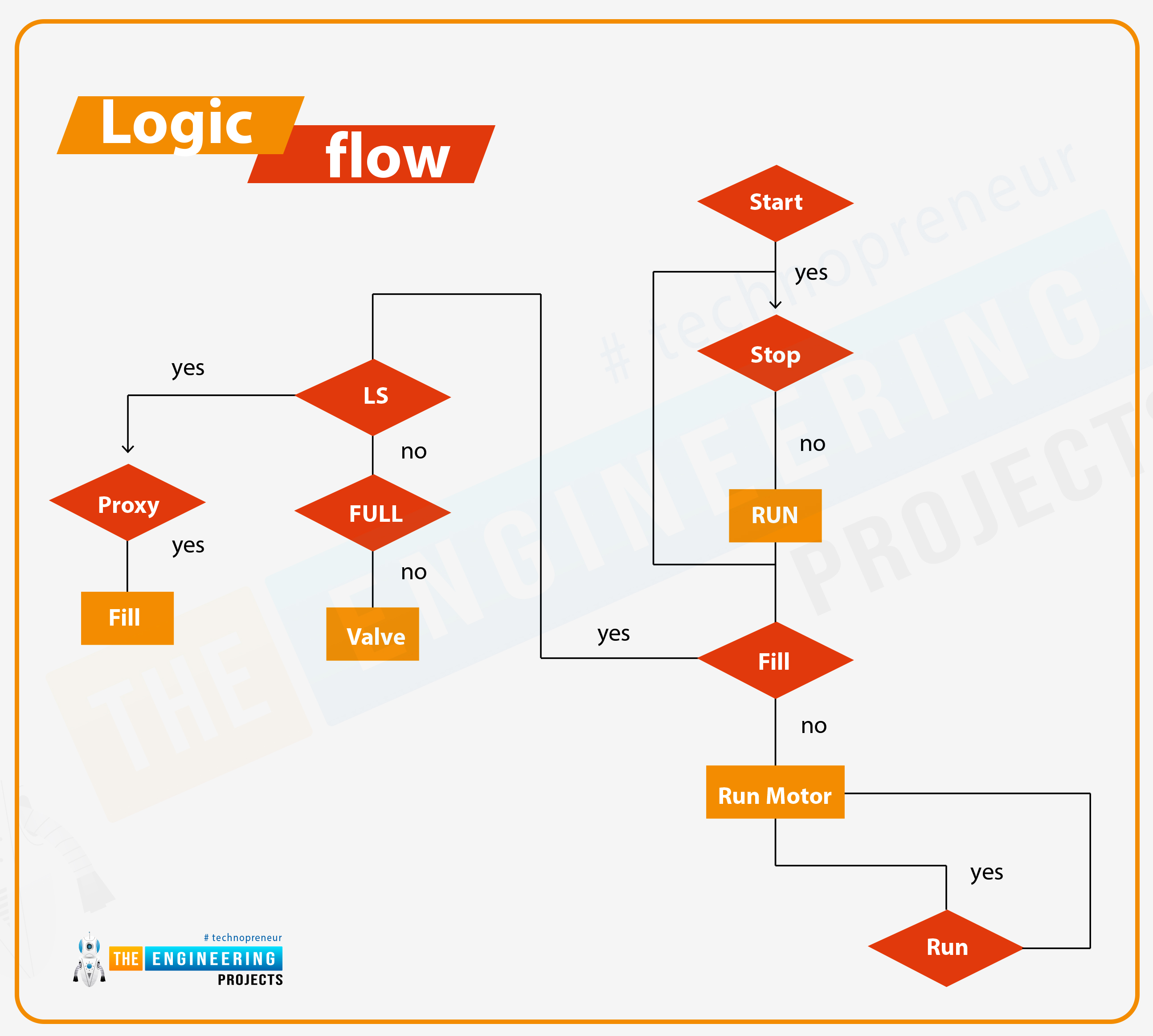

Logic Move Diagram

Guys, this isn’t a vital step to perform the challenge improvement. However this is without doubt one of the skilled methods to characterize graphically the design of the logic. Determine 3 depicts the logic of the silo challenge graphically. You possibly can observe paths of logic to know how we are able to chart the logic circulate working in our head graphically to assist in writing the right and exact code. For instance, to run the conveyor motor, the beginning button is pressed and checked if a cease is requested, if not the run lamp indicator shall be energized and latched so long as no cease is requested. Then test if a fill course of is in progress. If not then the motor of the conveyor will preserve working. However the query is find out how to know if the fill is in progress or not. On the left facet of the chart, you may see if the proxy swap is on and the extent swap doesn’t present full, then the filling course of is in progress. Additionally, if the extent swap exhibits not full then the valve will preserve open to proceed filling the bins.

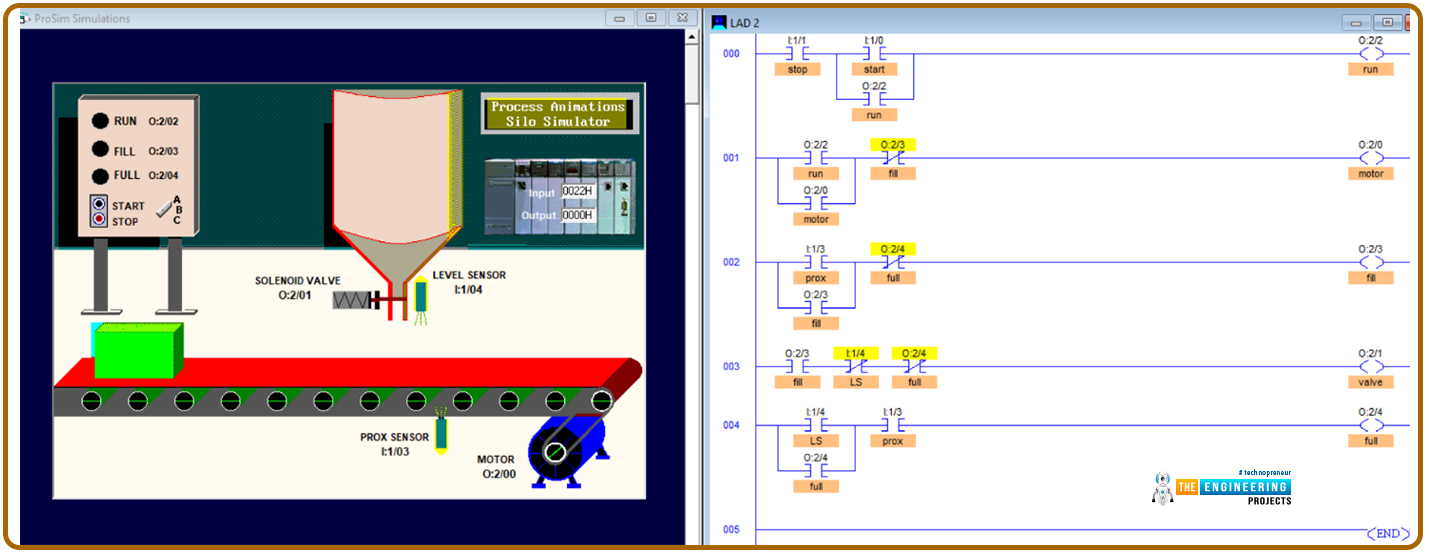

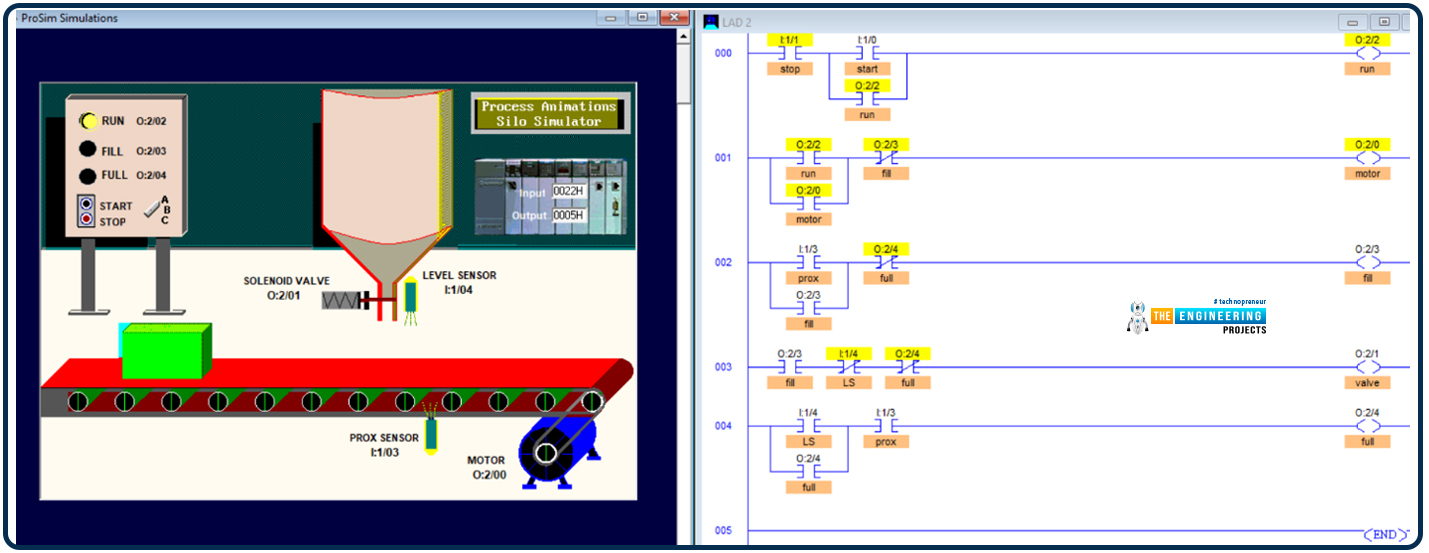

Ladder Logic Programming of the challenge

Now we’ve got simply arrived at what you’re ready for! I do know you wish to follow programming after which simulation. Determine 4 exhibits this system of the silo challenge whereas the left half exhibits the preliminary state of our simulation. The primary rung is to energise the run indicator when the beginning pushbutton is hit and no cease is requested noting the latch as we’ve got discovered. Within the second rung, understanding the run is the standing of the operation and no filling course of is in progress, then the motor is working. Within the third rung, the filling standing may be decided by the proximity swap displaying the boss is on the place have been able to fill and full standing will not be there. Whereas the total standing may be decided within the final rung when the extent swap is on displaying stage has reached the total restrict of the field and pursuing the proximity swap tells the field is on the filling spot. Earlier than that final rung, the valve of the silo may be decided by having the fill standing on and the total standing will not be there but.

Simulating this system

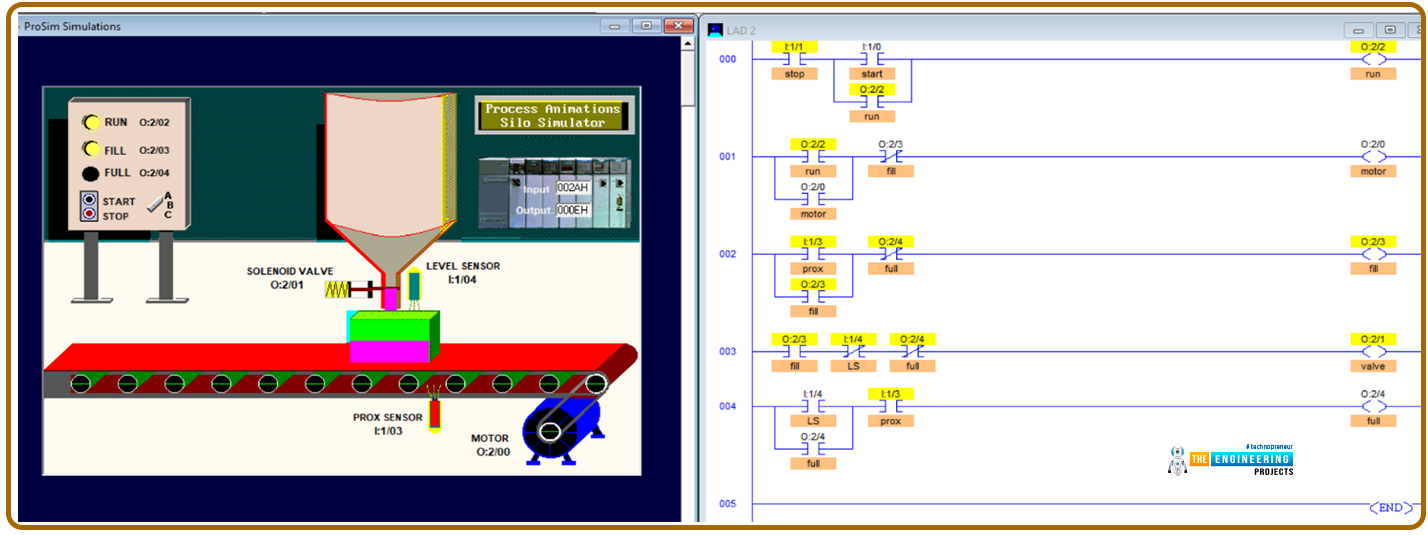

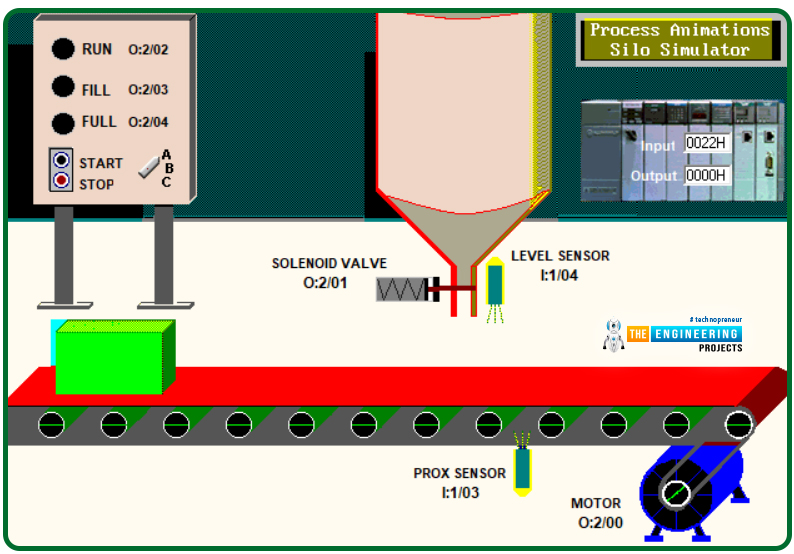

After displaying you the code of the design step-by-step based mostly on the obtained narrative from the shopper, deciding the IOs, and charting the logic of this system. Now it’s time to simulate this system to ensure the design and the code are right. Determine 5 exhibits the working standing of the operation. By hitting the beginning push button, the conveyor transfer by the driving motor and takes the field to the filling station. Guys, discover please the run indication lamp is on within the code highlighted in yellow and on the management panel on the correct as effectively. Additionally, discover the motor is spinning.

Determine 6 exhibits the field stopped for filling on the silo due to the proximity swap. Discover the run lamp is on and the motor is de-energized for letting the field fill. Additionally, discover the fill standing is on and the lamp indicator is energized. Additionally, see the valve is open to let the liquid fills the field.

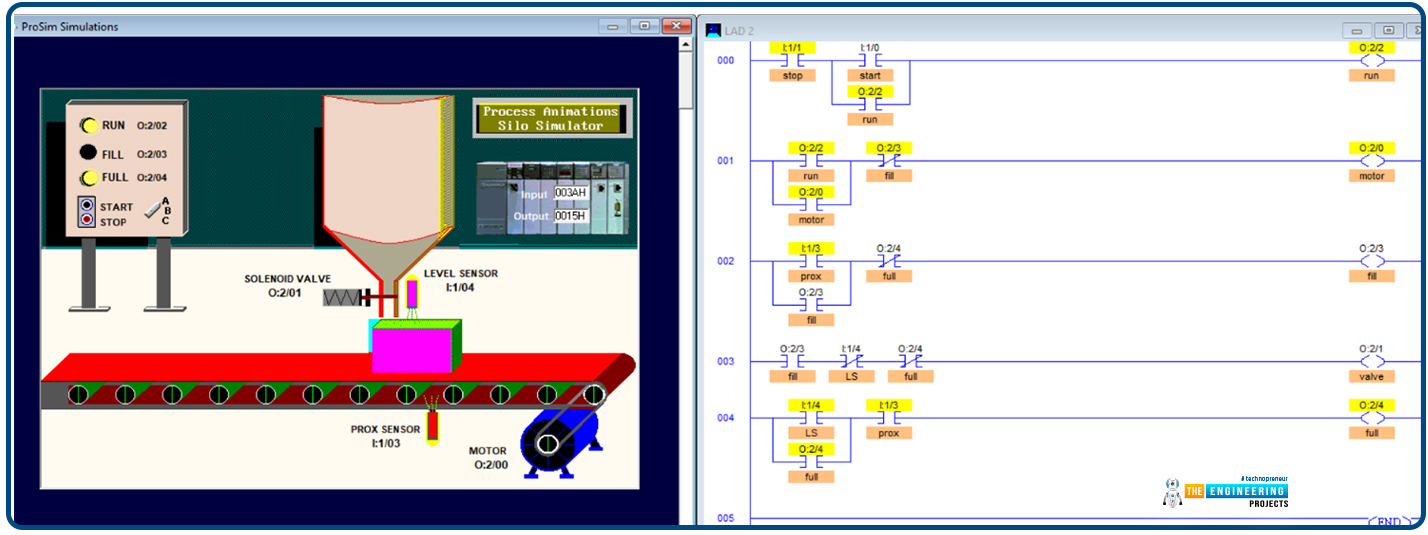

Determine 7 exhibits when the field involves be full. You possibly can see the run operation standing continues to be on. And the total standing is indicated by the total lamp. Additionally, as soon as the field is full, the motor begins spinning once more taking the crammed field out from the road to let different incoming bins come.

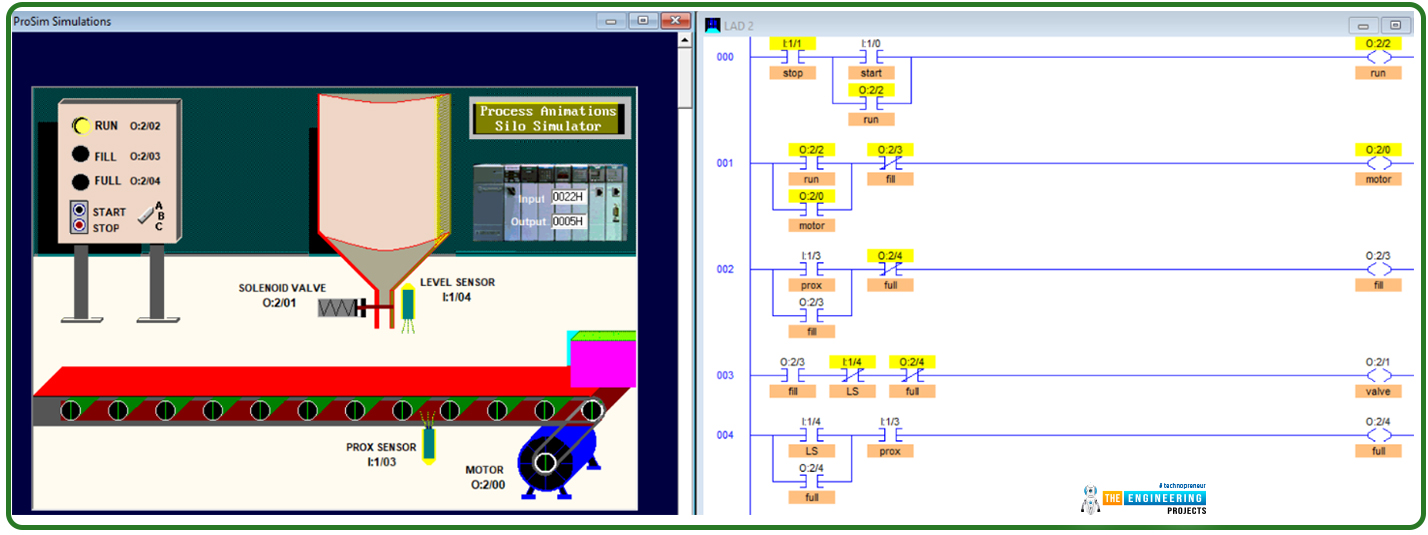

And eventually, after filling to full, the crammed bins preserve going as proven in determine 8 to the tip of the conveyor. You possibly can see the run standing continues to be energized and the motor is spinning. After that, the cycle will repeatedly be repeated till the cease is requested. So allow us to see the termination of the method.

however, when the cease push button is pressed requesting termination of the method, the motor stops spinning and the entire course of stopped till a continuing instruction is issued by hitting begin once more. Guys, that is quite common to allow the machine operator to cease for any emergence or do any repainting earlier than baking to work once more

What’s subsequent???

Initially, I wish to thanks all for proceed following the tutorial until this very level. As you see we’re taking initiatives from actual life. It is perhaps small initiatives or processes however that’s what you will note in actual trade life. So subsequent time we choose one of many frequent processes in the actual life and do the identical design, coding, and with out query working towards utilizing our simulator. So please be prepared, examine onerous, and let’s meet for our subsequent challenge.

https://pictures.theengineeringprojects.com/picture/important/2022/11/practice-ladder-logic-programming-with-a-real-time-project-5.jpg

https://pictures.theengineeringprojects.com/picture/important/2022/11/practice-ladder-logic-programming-with-a-real-time-project-5.jpghttps://pictures.theengineeringprojects.com/picture/important/2022/11/practice-ladder-logic-programming-with-a-real-time-project-5.jpg

0 Comments