Information briefs for the week check out robots unloading “floor-loaded cargo” from containers, trailer vehicles or railroad boxcars; unmanned floor vessels (USVs) and unmanned submersibles (UUVs) conducting completely autonomous missions, the place all vessels work collectively “collaboratively”; crumbling and rusty infrastructure with a sizeable payday forward for robotics builders with options to supply; and one more apple harvesting robotic taking over the elusive orchard problem.

Pickle Robotic’s loading-dock resolution nabs $26 million

As logistics distributors shut in on choosing, packing, and palletizing with their robots and cobots, the loading dock at warehouses nonetheless stays elusive to automate, says founder and CEO AJ Meyer of Cambridge, MA-based Pickle Robotic.

Unloading floor-loaded cargo from containers, trailer vehicles or railroad boxcars is sluggish and tedious for human labor…and harmful for on-the-job accidents (see video).

Unloading floor-loaded cargo from containers, trailer vehicles or railroad boxcars is sluggish and tedious for human labor…and harmful for on-the-job accidents (see video).

Exhausting to imagine that worldwide freight doesn’t all transfer on pallets, however a lot doesn’t, in line with transport specialists Ready & Womack: “To save cash, many distribution and success firms make the most of floor-loaded transport containers, although this transport methodology requires further labor to unload, palletize and test the stock in comparison with a palletized load. Flooring-loaded “can maintain extra, weigh much less and is often more economical as a result of freight financial savings.”

Pickle’s robotic, named Dill, relies round a KUKA arm able to as much as 30 kg of payload. It makes use of two Intel L515s (LiDAR-based RGB-D cameras) for field detection. The system is mounted on a wheeled base, and after getting positioned in the back of a trailer by a human operator, it’ll crawl ahead by itself because it picks its method into the trailer, say the oldsters at Pickle.

Amazon and Boston Dynamics, in addition to Siemens and Honeywell, have specialised, truck-unloading robots, however theirs additionally work “unsupervised.” Pickle, however, converts easy, off-the-shelf robots to do the unloading job, however recommends supervision by a human. Simplicity, ease of conversion, and the flexibility to scale quickly are a lot of the reasoning why traders simply loaded Pickle with $26 million in Collection A financing.

Amazon and Boston Dynamics, in addition to Siemens and Honeywell, have specialised, truck-unloading robots, however theirs additionally work “unsupervised.” Pickle, however, converts easy, off-the-shelf robots to do the unloading job, however recommends supervision by a human. Simplicity, ease of conversion, and the flexibility to scale quickly are a lot of the reasoning why traders simply loaded Pickle with $26 million in Collection A financing.

Pickle’s web site claims that Dill can “unload floor-loaded, non-palletized items at 600+ PPH” (600-plus packing containers per hour), incessantly in any sort of suboptimal work situations. “A single human in high type can transfer about 800 packing containers per hour.”

What then about “loading” a truck? Based on Business Week, fixing the three-dimensional puzzle of loading a trailer is harder than for unloading one. Atlanta/Shenzhen-based “Dorabot, which has backing from Chinese language e-commerce titan Jack Ma, is testing automated loading expertise with two clients.”

Dorabot’s AI-driven robots can load 400 parcels an hour right into a trailer, filling 60% of its capability — according to what an individual can do — stated Dorabot’s Chief Govt Spencer Deng. “Dorabot expects to enhance pace by about 50 parcels an hour, and fill 80% of a truck’s capability, earlier than going to market inside a yr and a half, Deng stated.”

Within the meantime, unloading, which is barely half the logistics battle in most warehouses and distribution facilities, seems to be closing in on a everlasting resolution, and Pickle Robotic is betting on Dill.

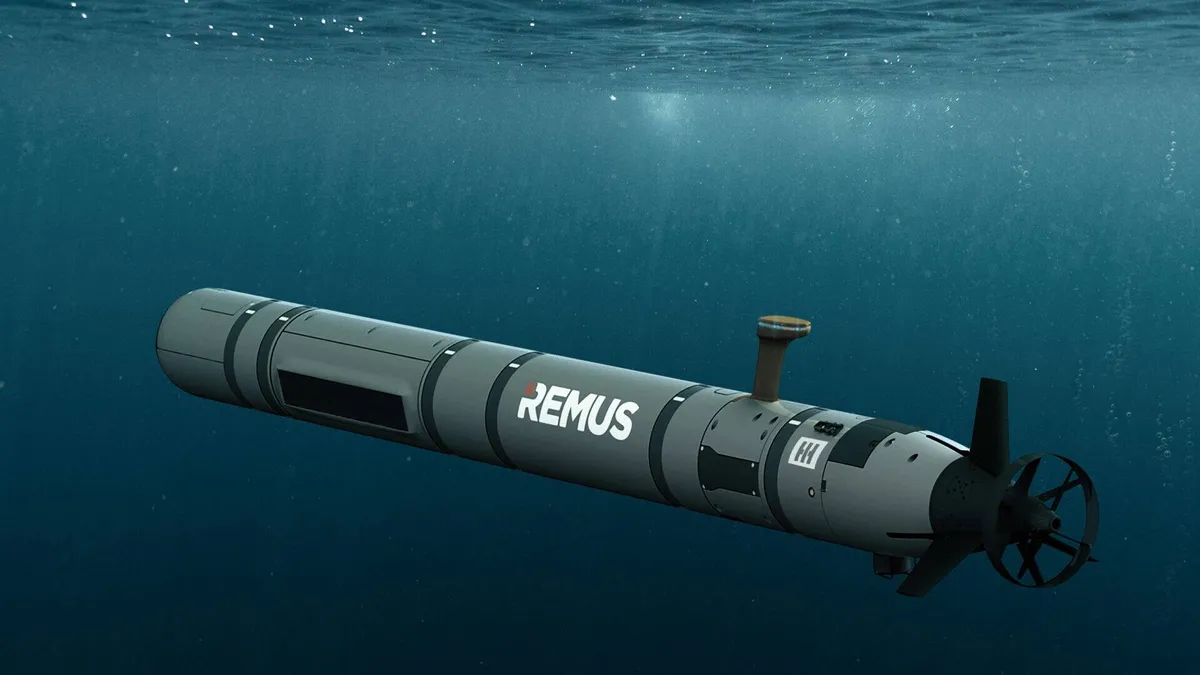

Torpedo-size sub as undersea “cobot”

How a few robotic submarine the dimensions of a torpedo working autonomously and collaboratively with different unmanned floor vessels (USVs) and bigger submersibles (UUVs) for joint, completely autonomous missions, the place all vessels work collectively collaboratively?

Meet the REMUS 620, a brand new technology of medium unmanned underwater car (MUUV) for mine clearing and countermeasures, hydrographic surveys, intelligence assortment, surveillance, cyber warfare and digital warfare.

Meet the REMUS 620, a brand new technology of medium unmanned underwater car (MUUV) for mine clearing and countermeasures, hydrographic surveys, intelligence assortment, surveillance, cyber warfare and digital warfare.

McLean, VA-based Mission Applied sciences, a division of HII (Huntington Ingalls Industries), not too long ago introduced the launch of the 32cm by 4.3meter submersible that weighs in at 320kg. REMUS, primarily based on expertise initially developed by Woods Gap Oceanographic Establishment, is a long-range endurance subsea robotic craft with a battery lifetime of as much as 110 hours and a spread of 275 nautical miles that may dive to 305 meters (1,000 toes).

Duane Fotheringham, president of Mission Applied sciences’ Unmanned Techniques enterprise group stated: “With a synthetic-aperture sonar put in, the REMUS 620 has a shorter battery lifetime of 78 hours and a shorter vary of 200 nautical miles. The MUUV can dash up at 8 knots with a navigation accuracy of 0.1% of distance traveled.”

Crumbling & rusty: America underneath the hood

Ever since President Biden signed the nation’s infrastructure invoice into regulation, Pittsburgh-based Gecko Robotics has been on a scorching streak with its inspection robots and evaluation software program.

Infrastructure is within the headlines all over the place, which implies that a sizeable payday is forward for robotics builders with one thing to supply.

Infrastructure is within the headlines all over the place, which implies that a sizeable payday is forward for robotics builders with one thing to supply.

Gecko Robotics, from the look of latest headlines, have to be at or close to the highest of that record. Right here’s the corporate’s latest headlines:

In June of 2022, Gecko (based in 2013), has been the topic of quite a lot of headlines: Industrial inspection startup Gecko Robotics raises $73 million. Then once more in October of 2022: Gecko Robotics Works With Siemens Vitality to Strengthen European Essential Infrastructure; after which once more in November of 2022: Gecko Robotics lands $1.5M contract with U.S. Air Pressure. All in six months!

Since 2016, the corporate has reeled in $122.3 million in investments.

“At Gecko, the mission of the corporate is to guard in the present day’s most crucial infrastructure and assist give type to tomorrow’s,” says Jake Loosararian, the robotic makers CEO and co-founder.

“At Gecko, the mission of the corporate is to guard in the present day’s most crucial infrastructure and assist give type to tomorrow’s,” says Jake Loosararian, the robotic makers CEO and co-founder.

Gecko builds robots, just like the Toka 4, that may “climb partitions, crawl throughout ceilings and navigate by way of pipes in a few of in the present day’s most vital infrastructure: energy vegetation, refineries, manufacturing websites, hydroelectric dams, and even ships and submarines.

“The robots analyze the property to grasp their structural integrity to anticipate once they’ll fail—and assist stop the failures from occurring within the first place.” (see video)

Every little thing ages and finally a reckoning arrives when every little thing must be repaired or changed, or else! The American Society of Civil Engineers estimates that $4.5 trillion is required to repair the nation’s roads, bridges, dams, and different infrastructure. The not too long ago handed Infrastructure Funding and Jobs Act of 2022 supplies $1 trillion towards that effort.

Gecko’s remote-controlled robots can climb vertically and horizontally, utilizing magnets to stick to all kinds of supplies.

Whereas climbing, the robots use ultrasonic transducers, localization sensors, lasers, and HD cameras to scan for put on, corrosion, cracks, blistering and different types of degradation. The evaluation is forwarded in actual time by way of Gecko’s software program for evaluation.

Are apple orchard robots lastly a viable various?

Even when there have been considerable employees to manually harvest apples, which isn’t the case any longer—a labor state of affairs worsening each day—there would nonetheless be a robust case to reap by way of robotic automation.

In the beginning, the sheer numbers of apples to be harvested is past mind-boggling. Washington State produces 5 billion yearly, most of that are nonetheless picked by hand. The king of apple growers is China with 43 billion yearly that every have to be handpicked.

And it not simply the mounting labor state of affairs; plenty of cash is available for whoever can clear up the robots on the farm conundrum. The chance for automating agriculture is big. A 2020 report by the consultancy McKinsey & Firm discovered autonomous farm equipment may add as much as $60 billion to world GDP by the top of the last decade.

And it not simply the mounting labor state of affairs; plenty of cash is available for whoever can clear up the robots on the farm conundrum. The chance for automating agriculture is big. A 2020 report by the consultancy McKinsey & Firm discovered autonomous farm equipment may add as much as $60 billion to world GDP by the top of the last decade.

One of many latest challengers is Australia-based Ripe Robotics and its robotic Eve.

Expertise is starting to assist to the robotic apple pickers. Laptop chips have change into a lot sooner and extra environment friendly, letting robots do extra complicated duties. Imaginative and prescient techniques, which allow them to establish gadgets, have improved dramatically, says Leopold Lucas, co-founder.

“Rural web is faster and extra dependable. And even some farming practices – like planting apple timber on trellises that make orchards simpler for machines to navigate – are serving to too”.

After all of the tech assist, nonetheless, the job falls to the robotic to do each night time and day, and in all types of climate situations.

“Ripe is doing trials this yr in offers with farmers the place it’s attempting to match human prices of about $60 per bin of apples picked. As soon as it proves its idea by choosing a full bin, it’s is hoping to lift $3 million to $5 million to rent employees and develop its fleet of robots.

Choose for your self if Eve is as much as the apple problem:

![]()

0 Comments