Relating to machine tending automation, the simplest to deploy options are nearly all the time these which can be easiest.

However does this imply you must select an intrusive or a non-intrusive answer?

Intrusive automation options are customized constructed in your particular wants. This implies they’re completely suited to your manufacturing line, however the integration course of is prolonged, complicated, and expensive. Non-intrusive automation options, then again, are fast to deploy and might be simply utilized to nearly any manufacturing line.

Which kind of answer is best? Customized intrusive automation or off-the-shelf non-intrusive automation?

With the proper data and a transparent understanding of each choices, you may make probably the most acceptable alternative in your machine tending course of.

What’s CNC machine tending and why automate?

Robotic machine tending is the method of utilizing robots to load and unload components from CNC machines. This often entails including uncooked supplies to the machine and eradicating the completed merchandise after the machining cycle.

Machine tending automation may also help enhance the effectivity of your manufacturing course of by eradicating this boring and repetitive activity from the palms of human employees.

These machinists can then transfer to extra useful and attention-grabbing duties inside your facility. This makes their jobs extra rewarding and helps enhance security as they aren’t interacting with harmful equipment.

Different advantages of automated machine tending is that it helps enhance product high quality by making certain components are all the time positioned within the machine in precisely the identical means each time.

Intrusive vs non-intrusive CNC machine tending

You’ll be able to consider there being two varieties of robotic machine tending answer: intrusive and non-intrusive.

Intrusive programs require in depth integration time and price range. You both want a excessive diploma of information and experience in robotic integration or you need to rent somebody who does.

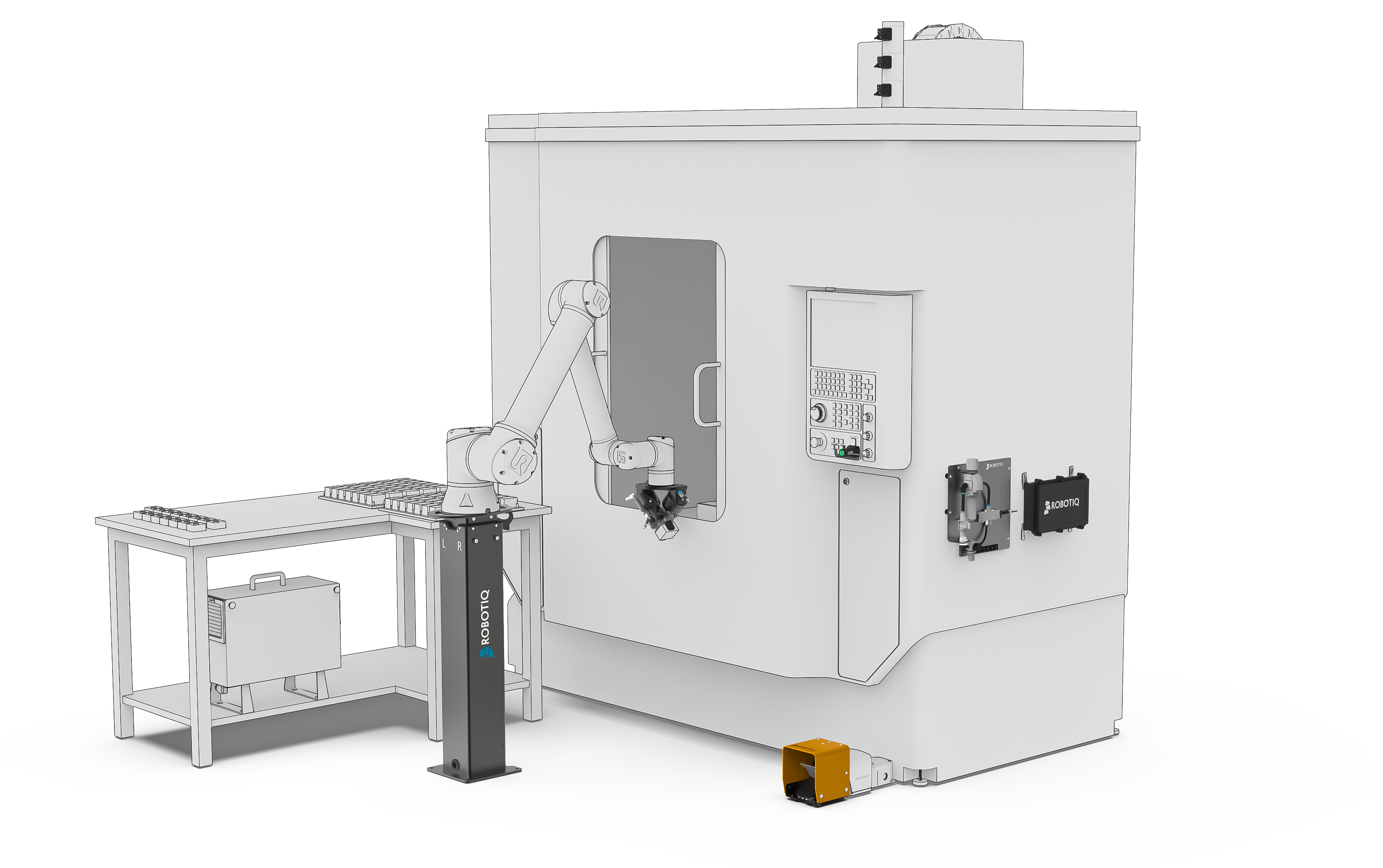

In distinction, a non-intrusive answer — the Robotiq Machine Tending Answer is the pioneer on this strategy — is predicated on customary, off-the-shelf applied sciences. Because of this straightforward strategy, you should use non-intrusive options with nearly any CNC machine.

Listed below are the professionals and cons of every strategy:

Intrusive machine tending options

That is the basic kind of robotic machine tending. Earlier than the Robotiq answer got here alongside, this was the one kind.

Intrusive options require you to combine with the CNC machine’s controller and {hardware} through the robotic’s programming.

Benefits of intrusive automation are:

Totally personalized to your particular machine.

Lets you entry all CNC machine performance, with superior programming.

Properly-established strategy, so there are lots of options available on the market.

Disadvantages are:

Integration is complicated and costly, taking numerous time.

Requires in depth robotics information and experience.

Arduous to enhance and replace following modifications to the method.

Non-intrusive machine tending options

The Robotiq Machine Tending Answer takes a really totally different strategy. It’s a non-intrusive answer.

Non-intrusive signifies that the answer makes use of customary applied sciences like gentle sensors and linear actuators. As an alternative of interfacing with the CNC machine’s communication protocols, the robotic system makes use of these off-the-shelf parts to work together as a human operator would — by trying on the standing lights and urgent buttons.

It is a less complicated, cheaper different and might be simply utilized to nearly any CNC machine.

Benefits of non-intrusive automation are:

Easier to deploy and really simple to make use of.

No robotics information or programming abilities wanted.

Suitable with many extra CNC machines.

Disadvantages are:

There are fewer options available on the market. Our answer is a pioneer.

Probably much less appropriate to full-scale automation throughout a complete manufacturing plant.

If you wish to entry extra superior performance of the CNC machine, you may want further integration.

How a non-intrusive machine tending answer works

How can a machine tending robotic interface along with your CNC machine with out utilizing the machine’s communication protocols?

With the Robotiq answer, we’ve got solved one of many greatest challenges with standard CNC machine tending utilizing a easy strategy.

The essential philosophy behind a non-intrusive system is that this: Use the CNC machine in the identical means as a human operator would.

This entails:

Utilizing gentle sensors to detect the CNC machine’s standing by “trying” at its standing lights.

Utilizing a linear actuator to press the machine’s foot pedal to open and shut the door.

Urgent the “Begin” button on the machine’s management panel to activate the subsequent machining cycle.

These options are very simple. With this strategy, we are able to take away an enormous quantity of the friction that’s generally related to machine tending automation.

How to decide on the proper kind of automation for your small business

Discovering the proper automation answer for your small business generally is a powerful determination. There are numerous competing options available on the market. To the untrained eye, these options can appear to be fairly related, even when they’re really very totally different.

There isn’t any one-size-fits-all for automation — though the Robotiq Machine Tending Answer comes shut. A number of elements will affect your alternative of answer, together with the scale of your organization, the quantity of automation you wish to deploy, and the precise wants of your machinists.

No matter machine tending answer you select, attempt to discover examples of people that have finished the identical as you. You could find some examples of groups which have utilized machine tending automation in our case research library.

Your alternative: customized vs. off-the-shelf automation

In the end, the selection of whether or not you automate with an intrusive or a non-intrusive answer is as much as you.

With the proper data and steerage, you may make one of the best determination in your wants, price range, and stage of expertise.

Crucial factor is to discover a answer that can assist you to automate your particular CNC machines. With the proper answer, you’ll be a part of the various companies which can be utilizing robots to make their manufacturing extra environment friendly.

You may as well see our Machine Tending Answer in motion on this demo.

What has held you again from machine tending automation till now? Inform us within the feedback under or be a part of the dialogue on LinkedIn, Twitter, Fb, or the DoF skilled robotics group.

0 Comments